PLACE to build. collaborate. optimize. innovate. grow.

Ihre erfahrenen Experten für mehr Effizienz,

Qualität und Erfolg Ihrer Bauprojekte.

Lean Construction

Digitales Lean Management im Bauwesen

Digitales Lean Management im Bauwesen mit Fokus auf Lean Construction: Wir bei PLACE verstehen, dass die Bauindustrie ständig nach effizienteren Methoden sucht, um Projekte zu planen und auszuführen. Mit Lean Construction bieten wir eine innovative Lösung, die Material-, Zeit- und Arbeitsaufwand minimiert, um den größtmöglichen Wert zu generieren.

Was ist Lean Construction? Lean Construction ist mehr als nur eine Methode – es ist eine Philosophie. Es ist eine Möglichkeit, Produktionssysteme im Bauwesen so zu konzipieren, dass Material-, Zeit-, und Arbeitsaufwand minimiert werden, um den größtmöglichen Wert zu generieren.

Im Gegensatz zu klassischen Projektmanagement Methoden, erfüllt Lean Construction den Nutzen, Bauprojekte innerhalb eines vorgegebenen Budgets, zur vereinbarten Zeit und in vereinbarter Qualität zu liefern. Mit Lean Construction können Sie Ihre Bauprojekte optimieren und gleichzeitig die Produktivität steigern.

Ihr Projekt –

Unsere Lösung.

Mit PLACE an Ihrer Seite etablieren Sie eine neue, stressfreiere Art des Projektmanagements. Mit Lean Construction gehören Doppelarbeit und Koordinationsschwierigkeiten bald der Vergangenheit an und Sie können sich endlich Ihrer eigentlichen Arbeit widmen. Unser Team an erfahrenen Lean Construction Experten begleitet Sie bei jedem Schritt auf dem Weg zur Lean Transformation Ihres Unternehmens.

Lean Construction Beratung

Als spezialisierte Lean Construction Beratung hilft PLACE, Ihr Bauprojekt agil und effizient zu gestalten. Wir begleiten Ihr Bauvorhaben mit einer tagesgenauen Arbeitsplanung, einer neutralen Moderation Ihrer wöchentlichen Lean Besprechungen und unterstützen Sie bei der Analyse vergangener Wochen und der Optimierung zukünftiger Arbeitsprozesse im Kontext von Lean Construction.

Lean Transformation

Eine Lean Transformation hilft bei der Optimierung aller Geschäfts- und Arbeitsprozesse. Durch die kontinuierliche Verbesserung aller Prozesse, Dienstleistungen und Produkte im Unternehmen werden wichtige Ressourcen eingespart und essenzielle Kundenbedürfnisse erfüllt.

Terminsteuerung

Eines der wichtigsten Elemente in der Lean Construction ist die Terminplanung. Diese besteht aus 6 Phasen, die dazu beitragen, dass das Bauprojekt mit allen Zielen, beteiligten Personen, Projektplänen und benötigten Ressourcen definiert, geplant und implementiert wird, um Ihr Bauprojekt erfolgreich umzusetzen.

Das sagen unsere

Kunden über uns:

Joachim Hölzel

Geschäftsführer

Bankwitz GmbH

“Seit wir mit PLACE zusammenarbeiten gibt es eine wesentlich koordiniertere Planung und wir haben wesentlich kürzere Planungszeiten […]”

Christoph Rahrbach

Teamlead General Construction

Pharmaplan GmbH

“Meine Erfahrung mit den Mitarbeitern von PLACE ist, dass sie auf den Baustellen viele persönliche Erfahrungen gesammelt haben und sie auch wissen was hinter den Prozessen in einem Planungs- oder Bauprojekt steckt. […]”

Christian Denzinger

Stellv. kaufm. Leiter

Gottlob Rommel Gruppe

“Seit wir mit PLACE zusammenarbeiten haben wir einiges an Bauzeit eingespart und konnten Schnittstellenprobleme auf Baustellen lösen. […]”

Lean Construction Schulung

Unsere Lean Construction Schulung und die Zertifizierung nach VDI 2553 sind die perfekte Kombination, um Ihre Projekte erfolgreicher und effizienter zu gestalten. In unserer Lean Construction Schulung lernen Sie, wie Sie die Methoden und Tools der Lean Construction anwenden und Ihre Projekte erfolgreicher gestalten können.

Lean Construction Tools: Unser Haftnotizshop

Wichtige Bestandteile von Lean Construction sind Transparenz und Kollaboration. Ein einfacher Weg beides zu erreichen ist die Verwendung von Haftnotizen, die als visuelle Hilfe dienen, um Prozesse zu planen und zu überwachen.

Ausgewählte

Referenzen

Lean Construction:

Agile und schlanke Bauprojekte

Lean Construction: Einführung und Vorteile

Lean Construction ist eine innovative Methode zur Optimierung von Bauprojekten. Sie basiert auf den Prinzipien des Lean Managements, die ursprünglich in der Automobilindustrie entwickelt wurden. Ziel ist es, Verschwendung zu reduzieren, die Effizienz zu steigern und die Produktivität auf Baustellen zu erhöhen. Mit Lean Construction können Sie Ihre Bauprojekte optimieren und gleichzeitig die Produktivität steigern.

Grundlagen und Prinzipien von Lean Construction

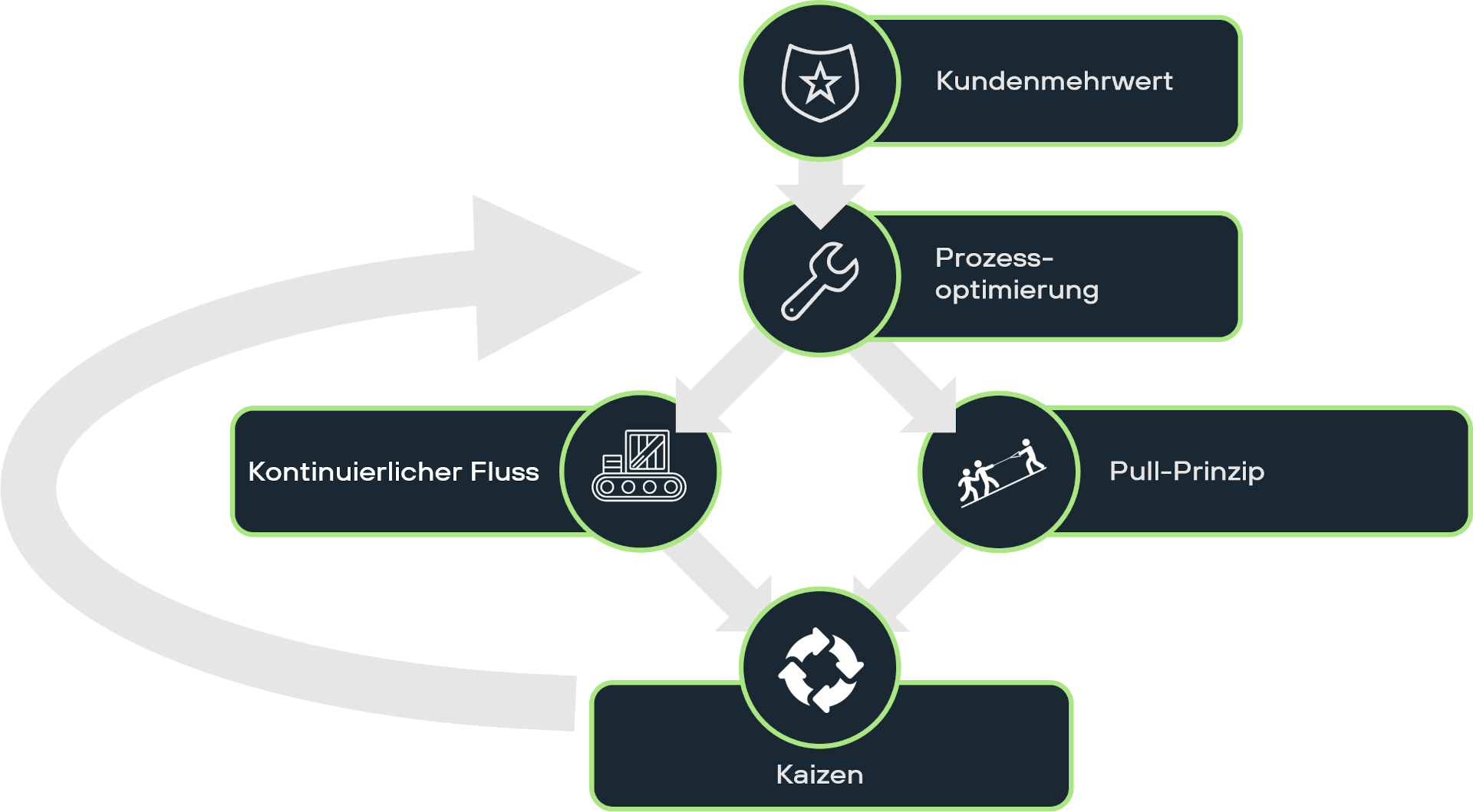

Lean Construction basiert auf fünf grundlegenden Prinzipien:

- Kundenmehrwert: Die Bedürfnisse und Anforderungen der Kunden stehen im Fokus, um den größtmöglichen Wert zu schaffen.

- Prozessoptimierung: Die Effizienz von Arbeitsabläufen wird kontinuierlich verbessert, um Verschwendung zu minimieren.

- Pull-Prinzip: Ressourcen und Materialien werden bedarfsorientiert bereitgestellt, um Überproduktion und Lagerhaltung zu reduzieren.

- Flow-Prinzip: Die Arbeitsabläufe werden so gestaltet, dass sie reibungslos und ohne Verzögerungen ineinander übergehen.

- Kaizen: Die kontinuierliche Verbesserung aller Prozesse und Arbeitsabläufe bildet die Grundlage für eine nachhaltige Optimierung.

Vorteile von Lean Construction für Bauprojekte

Effizientere Prozesse und reduzierte Baukosten

Durch die Anwendung von Lean Construction können Bauunternehmen ihre Prozesse optimieren und somit Zeit und Kosten sparen. Die kontinuierliche Verbesserung der Arbeitsabläufe führt zu einer höheren Effizienz und reduzierten Baukosten.

Verbesserte Qualität und Kundenzufriedenheit

Die Fokussierung auf die Bedürfnisse der Kunden und die kontinuierliche Verbesserung der Prozesse führen zu einer höheren Qualität der Bauwerke. Dies wirkt sich positiv auf die Kundenzufriedenheit aus.

Erhöhte Flexibilität und Anpassungsfähigkeit

Durch die Just-in-Time-Produktion und die flexible Gestaltung der Arbeitsabläufe kann auf Änderungen im Bauprojekt schneller und besser reagiert werden. Dies erhöht die Anpassungsfähigkeit und reduziert das Risiko von Verzögerungen und Mehrkosten.

Effektive Methoden für Lean Construction in Bauprojekten

Last Planner System

In Bauprojekten ist das Last Planner System besonders relevant, da es den Fokus auf die Zusammenarbeit und Kommunikation der Projektbeteiligten legt. Dies trägt zur besseren Koordination der unterschiedlichen Gewerke bei, was wiederum zu weniger Verzögerungen und Fehlern führt. Die regelmäßige Überprüfung und Anpassung der Pläne an aktuelle Gegebenheiten gewährleistet eine optimierte Planung und ermöglicht ein frühzeitiges Erkennen von Problemen. Im Bereich der Suchmaschinenoptimierung ist es entscheidend, relevante Schlagworte wie „Last Planner System“, „Koordination“ und „Planungsoptimierung“ in den Text einzubinden, um eine gute Sichtbarkeit bei entsprechenden Suchanfragen zu erreichen.

Taktplanung

Die Anwendung von Taktplanung in Bauprojekten trägt zur Optimierung von Arbeitsabläufen und Ressourcennutzung bei. Durch die systematische Einteilung der Baustelle in Taktbereiche und die Festlegung von Taktzeiten wird die Ausführung von Bauprojekten effizienter gestaltet. Das gezielte Einbinden von Schlüsselbegriffen wie „Taktplanung“, „Ressourcenmanagement“ und „Arbeitsabläufe“ im Text kann die Auffindbarkeit bei Suchmaschinen verbessern und den Inhalt für potenzielle Interessenten relevanter machen.

Building Information Modeling (BIM)

Die Integration von Building Information Modeling (BIM) in Bauprojekte ermöglicht eine effizientere Planung, Ausführung und Überwachung der Projekte. BIM erleichtert die Zusammenarbeit zwischen den verschiedenen Projektbeteiligten und sorgt für eine transparente Informationsverwaltung. Um die Sichtbarkeit bei Suchmaschinen zu erhöhen, sollten Begriffe wie „BIM“, „digitale Planung“ und „Lebenszyklus“ gezielt in den Text eingefügt werden. Dies erhöht die Relevanz des Inhalts und macht ihn für Interessenten leichter auffindbar.

Target Value Design (TVD)

Target Value Design (TVD) wird in Bauprojekten eingesetzt, um Kostenziele frühzeitig festzulegen und eine kostenbewusste Entscheidungsfindung zu fördern. Dies trägt dazu bei, die Anforderungen des Kunden, die Qualität des Bauwerks und die verfügbaren finanziellen Ressourcen besser aufeinander abzustimmen. Um die Auffindbarkeit des Inhalts bei Suchmaschinen zu optimieren, sollten Begriffe wie „Target Value Design“, „Kostenschätzung“ und „wertorientierte Planung“ im Text verwendet werden. Dadurch erhöht sich die Relevanz des Inhalts und die Sichtbarkeit bei entsprechenden Suchanfragen.

FAQ: Ihre Fragen zu Lean Construction beantwortet

Lean Construction

Was versteht man unter Lean?

Lean ist ein Managementansatz, der darauf abzielt, Prozesse zu optimieren und Verschwendungen zu vermeiden. Dabei werden Methoden und Werkzeuge eingesetzt, um die Effizienz und Qualität von Prozessen zu verbessern und den Kundenwert zu steigern. Der Lean-Ansatz wurde ursprünglich in der Automobilindustrie entwickelt und basiert auf dem Toyota Production System (TPS). Inzwischen wird er jedoch in vielen anderen Branchen angewendet, darunter auch im Bauwesen.

Was bedeutet Lean Construction Management?

Lean Construction Management bedeutet, dass Sie alle Phasen eines Bauprojekts optimieren und so organisieren, dass Ihre Prozesse «lean» (aus dem Englischen: schlank und effektiv) werden. Lean Construction wurde auf den Grundlagen des Lean Managements entwickelt. Dabei wurden die grundlegenden Gedanken aufgenommen und darauf aufbauend neue Methoden entwickelt, um die Prinzipien auf die Baubranche anwenden zu können.

Wie kann ich als Unternehmen in der Bauwirtschaft Lean Construction in meinen Projekten anwenden?

Um mit der Anwendung von Lean Construction in Bauprojekten zu beginnen, kann ein Unternehmen zunächst eine Bestandsaufnahme durchführen, um die aktuellen Prozesse und Herausforderungen zu identifizieren. Danach kann es Schulungen und Workshops für das Team durchführen, um Kenntnisse und Fähigkeiten im Lean Construction zu erlangen. Es kann auch Pilotprojekte starten, um die Methode in der Praxis auszuprobieren und Erfahrungen zu sammeln, bevor man sie auf größere Projekte ausweitet.

Warum Lean Construction?

Professionelles Lean Construction Management durch PLACE kann wichtige Vorteilen über die Dauer des gesamten Bauprozesses erzielen:

– Fokus auf effizientes Produktionssystem: Lean Construction legt den Fokus auf ein effizientes und funktionierendes Produktionssystem, um Verzögerungen und Mängel im Idealfall so schnell wie möglich und vorausschauend zu beseitigen.

– Mehrwertorientiert: Lean wird gemäß den Lean Prinzipien mehrwertorientiert umgesetzt. Im klassischen Projektmanagement rückt der Mehrwert oftmals in den Hintergrund und ineffiziente Arbeitsprozesse mit Tunnelblick sind das Resultat.

– Transparente, kollaborative Zusammenarbeit: Lean Construction fördert eine transparente und kollaborative Zusammenarbeit, mit einer gesunden Fehlerkultur (Fehler sind unvermeidbar und sollten nicht verheimlicht werden). Die Planung von Puffern auf der Baustelle erfolgt ebenso transparent, sodass überzogene Puffer Einplanungen der Vergangenheit angehören.

– Kontinuierliche Verbesserung und Lernen während des Projekts: Wird Lean im Bauwesen angewendet, werden präzise Kennzahlen entwickelt. Anhand diesen werden entsprechende Prozesse aufgenommen, die fortlaufend evaluiert werden. Dadurch findet von Woche zu Woche eine Verbesserung in Bereichen wie der persönlichen Einschätzung und der Zusammenarbeit der Beteiligten statt.

Wie kann Lean Construction in der Bauindustrie die Nachhaltigkeit fördern?

Lean Construction kann die Nachhaltigkeit in der Bauindustrie fördern, indem es Verschwendung minimiert und die Ressourceneffizienz erhöht. Durch die Anwendung von Lean-Methoden kann sichergestellt werden, dass nur die erforderlichen Materialien und Ressourcen eingesetzt werden und Abfall reduziert wird. Es kann auch dazu beitragen, die Umweltauswirkungen von Projekten zu minimieren, indem es den Energie- und Wasserverbrauch reduziert und die Verwendung von umweltfreundlichen Materialien fördert.

Lean Beratung

Was sind die 5 Lean Prinzipien?

Lean Management im Bauwesen als auch in anderen Bereichen wird stets von 5 Prinzipien bestimmt, die zusammen die Leitsätze des Lean Management bilden:

– Kundenmehrwert

– Prozessoptimierung

– Flusseffizienz

– Pull-Prinzip

– Kaizen

Hier finden Sie alle Details rund um die fünf Lean Prinzipien.

Warum ist Lean Transformation wichtig?

Durch den strategischen Einsatz verschiedener Lean Methoden können alle Geschäfts- und Arbeitsprozesse eines Unternehmens möglichst effizient gestaltet werden und führen dadurch eine Lean Transformation herbei.

Der kontinuierliche Einsatz von Lean Methoden eliminiert nutzlose und kostspielige Verschwendungen und spart wertvolle Ressourcen ein, die dazu beitragen, dass die allgemeine Produktivität verbessert wird und die Qualität der Produkte und Dienstleistungen steigt.

Eine Lean Transformation ist wichtig, da sie eine effiziente und vorhersehbare Auslieferung von Projekten ermöglicht. Eine exakte Planung in Abstimmung mit allen Beteiligten führt zur Vermeidung von Verzögerungen und unnötigen Verschwendungen, da jeder Arbeitsschritt in sich durch Lean Methoden optimiert wird.

Hier erfahren Sie alles rund um Lean Transformation.

Was ist Taktplanung?

Bei der Taktplanung wird jeder einzelne Prozessschritt in einem Bauprojekt definiert. Diese Art der Planung erzielt eine optimale Abstimmung zwischen allen Gewerken, wodurch die Bauzeit beschleunigt wird, sowie Kosten und Qualität optimiert werden.

PLACE unterstützt Sie bei der digitalen Taktplanung und sorgt für reibungslose Arbeitsabläufe auf Ihrer Baustelle. Der digitale Takt- und Terminplan ist zudem online abrufbar: Alle Projektbeteiligte können ihn zu jeder Zeit einsehen – so wird Ihre getaktete Baustelle im Handumdrehen fertig!

Hier erfahren Sie alles zur Taktplanung.

Was ist das Last Planner System?

Das Last Planner System ist ein kollaboratives Produktionsmanagementsystem, welches Menschen, Systeme und Geschäftsprozesse in einem Bauprojekt visuell miteinander verbindet. Das System basiert auf den 5 Prinzipien des Lean Construction Management. Dabei hilft das Last Planner System, Verschwendungen zu reduzieren oder, im besten Fall, zu eliminieren. Die Nutzung von Ressourcen wird optimiert, wodurch die Produktivität und Effizienz des Bauvorhabens und die Kundenzufriedenheit steigen, da sich Zuverlässigkeit und Vorhersehbarkeit des Produktionsprozesses bestimmen lassen.

Hier finden Sie alles zum Last Planner System.

Welche Lean Methoden gibt es?

Im Lean Construction Management gibt es eine Reihe von unterschiedlichen Methoden, die angewendet werden können, um Prozesse effizienter zu gestalten und Mehrwert zu erzeugen.

Target Value Design (TVD)

Das Target Value Design ist ein kollaborativer Planungsprozess, an dem Planer, Bauherren, Zulieferer und alle anderen Projektbeteiligten gemeinsam einen Entwurf erstellen, der dem Eigentümer den größten Mehrwert liefert.

TVD beruht auf 5 fundamentalen Kriterien:

– Das Budget für die Planung festsetzen

– Arbeitsstrukturierung

– Kollaboration

– Selbstständiges Planen

– Kollokation/An einem Ort versammelt

5S Methode

Die 5S-Methode ist eine systematische Vorgehensweise, um den eigenen Arbeitsplatz und die Arbeitsumgebung so zu gestalten, dass man sich optimal auf die wertschöpfenden Tätigkeiten konzentrieren kann. Dabei wird Verschwendung in diesem Zuge eliminiert oder reduziert. Im 5S-Zyklus durchläuft man insgesamt fünf Einzelschritte:

– Sortieren

– Systematisierten

– Säubern

– Standardisieren

– Stetige Verbesserung

Lean & Six Sigma

Six Sigma (6 σ) ist ein Managementsystem zur Prozessverbesserung. Dabei werden statistische Qualitätsziele beschrieben, gemessen und analysiert. Gleichzeitig ist Six Sigma eine Methode des Qualitätsmanagements, mit der sich Geschäftsprozesse und deren Verbesserung überwachen und statistisch auswerten lassen.

Lean und Six Sigma verfolgen ähnliche Ziele, wobei sich die eingesetzten Methoden sich teilweise unterscheiden. Durch eine intelligente Kombination der beiden Systeme ergänzen sich diese hervorragend und schaffen so Effizienz ganz im Sinne des Kundenmehrwerts.

Hier erfahren Sie alles zu den Lean Grundlagen.